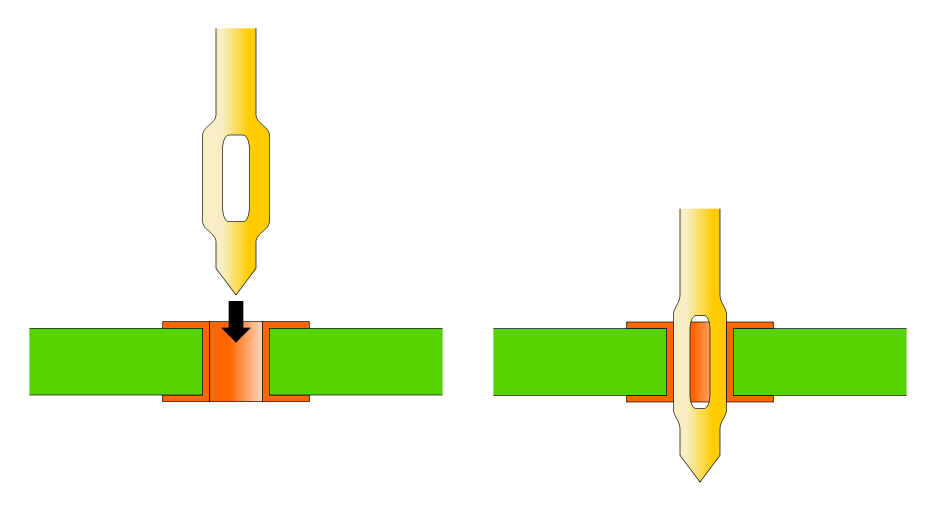

Press-fit technology is a solder-free electrical-mechanical connection technology between component and circuit board. For this purpose, a press-fit pin is pressed into the through-hole plating of the circuit board. At the contact points between the pin and the hole wall, gas-tight zones are created by cold welding the contact materials.

As an alternative to THT or SMT soldering, the press-fit technology helps to avoid thermal stress and ensures a high level of reliability of the connection and (in the solid pin version) a high current carrying capacity.

Press-fit technology requires a low tolerance of the hole diameter and is therefore special production.

You should define an extra layer for press-fit technology and output this as an extra drilling program at Gerber export. ODB++ data contain the information automatically! If you would like to use our data import service (e.g. for EAGLE, KiCad, …) please inform us of the relevant layer.

Advantages of press-fit technology:

- High reliability of the connection with extremely low FIT value (Failure in Time)

- No thermal stress on the connection components thanks to solderless assembly

- High holding forces: pins make gas-tight contact in the metallized drill holes

- Efficient assembly process: press-in process using a toggle lever or pneumatic press