Product Category

Contact

sabrina.he@hjssmt.com

+86 15989403900

+86 15989403900

+86 15989403900

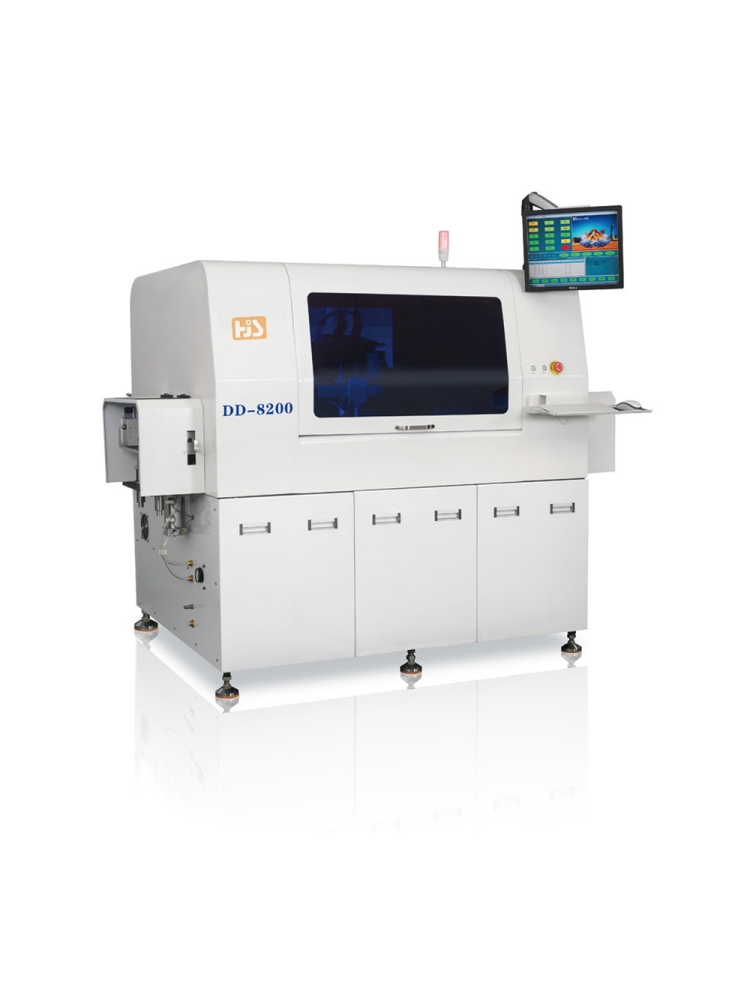

Automatic Radial Insertion Machine DD-8200

DD-8200 automatic high-speed radial insertion machine automatically inserts various non-standard braided radial components into the printed circuit board (PCB) according to the set procedures of different products. It has the functions of fixed bending angle and detection, so as to achieve high speed, high precision and high stability.

Radial lead component insertion machine, universal radial insertion machine.

Features:

1、 Operating system: operating software running under Windows environment, production data, management data, equipment parameters, editing program, all I / O signal diagnosis, etc. can be completed on the host computer. The user-friendly interface and the application of high-tech technology make the equipment simple, efficient, easy to use and good operability.

2、 Plug in speed: 1 second / piece, using Panasonic AC servo drive, high speed, low noise, stable motion.

3、 Vision system: the vision system is composed of industrial high-definition camera and self-developed vision correction software. The deviation between PCB hole position and coordinates input in programming can be seen, and all coordinates can be quickly and automatically aligned with the actual PCB hole position, so as to ensure the accuracy of the plug-in and greatly improve the programming efficiency.

4、 Leakage detection: when the leakage is inserted, it can realize the leakage detection and has the function of interpolation.

5、 Important parts suppliers:

A. The servo motor adopts Panasonic brand.

B. The motor of plate feeding and docking station system adopts Oriental brand.

C. AIRTAC brand is used for pneumatic components.

D. The lead screw adopts Kuroda brand of Japan.

E. The camera system adopts super light image (5 megapixel) brand.

F. The relay adopts Omron brand of Japan.

G. The photoelectric sensor adopts SUNX brand. H. The main parts are made of Japanese die steel.

Specification:

| 1 | Theoretical rate | 22000PCS/H |

| 2 | Insertion rate | Less than 1000PPM |

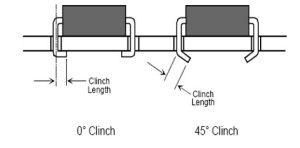

| 3 | Insert direction | Parallel 0 degrees, 90 degrees |

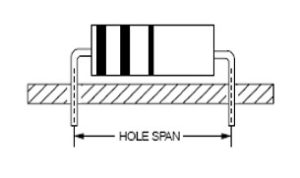

| 4 | Component span | Double hole distance 5.5MM-18MM (insert jumper 5MM-25MM) |

| 5 | PCB size | Min 50MM x 50MM, max 330MM x 260MM |

| 6 | PCB thickness | 0.79-2.36MM |

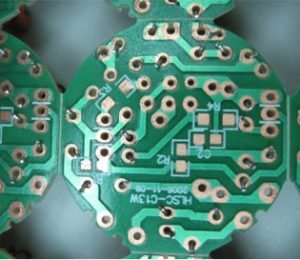

| 7 | Types of components | Capacitors, transistors, diodes, resistors, fuses, etc. |

| 8 | Jumper (JW) | Independent mode of transport. Diameter 0.5MM-0.7MM tinned copper wire |

| 9 | The length of the component leader shear | 1.2-2.2MM (adjustable) |

| 10 | The angle of lead | 0-35 degrees (adjustable) |

| 11 | Machine size (length, width, height) | 1.95 meter*1.3 meter*1.6 meter |

| 12 | Machine weight | 1800KG |

| 13 | power supply | 220V,AC(single phase)50/60HZ,1000VA; |

| 14 | Use power | 1.6KW (energy-efficient) |

| 15 | Use air pressure | 0.5MPA or more |

| 16 | Gas | Less than 0.2 m3/min |

| 17 | Ambient temperature | Below 29 degrees Celsius. |

| 18 | Machine noise | 65 decibels |

| 19 | The hole correction method | Image vision system, multipoint MARK visual correction. |

| 20 | Drive system | AC servo, AC motor |

| 21 | How the data is entered | USB Interface Input (EXCEL document format), |

| 22 | Control system | (WINDOWS system control platform) Dell LCD display |

| 23 | Convey method | Automatic |