Product Category

Contact

sabrina.he@hjssmt.com

+86 15989403900

+86 15989403900

+86 15989403900

Automatic Axial Insertion Machine DD-8800

High speed axial insertion machine, automatic insertion machine, axial component insertion machine, with best price.

Applied for home appliances/power supply/DVB/audio/lighting/instrument and other electronic industries.

Specification parameters

| 1 | Cycle rate | 20000PCS/H |

| 2 | Insertion rate | Less than 1000PPM |

| 3 | Insert direction | 360 degrees in increments of 1 degree |

| 4 | Lead span | Spacing 2.5/5.0/7.5MM/10MM |

| 5 | PCB size | Min 100MM x 100MM, max 380MM x 280MM (plus customizable) |

| 6 | PCB thickness | 0.79-2.36MM |

| 7 | Component specifications | The maximum height is 23MM and the maximum diameter is 13MM |

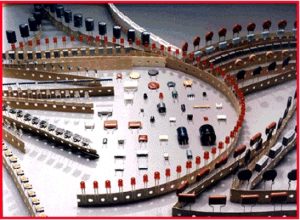

| 8 | Types of components | LED lamps, capacitors, transistors, tripods, iso-vertical reel packaging materials. |

| 9 | Lead length | 1.5±0.1MM |

| 10 | Lead bending angle | 10-35 degrees (adjustable) |

| 11 | Number of station | 10 -20 stations |

| 14 | power supply | 220V, AC (single phase) 50/60HZ, |

| 15 | UPS | It can run for 15 minutes after a power outage |

| 16 | Use power | 2KW (energy-efficient) |

| 17 | Use air pressure | 0.6MPA or more |

| 18 | The amount of gas used | Less than 0.3 m3/min |

| 19 | ambient temperature | Below 29 degrees Celsius. |

| 20 | Machine noise | Less than 65 decibels |

| 21 | The hole correction method | Image vision system, multipoint MARK visual correction. |

| 22 | Drive | AC servo, AC motor |

| 23 | How the data is entered | USB interface input (EXCEL document format), |

| 24 | Control system | Chinese operator interface (WINDOWS system control platform) Dell LCD display |

| 25 | Component density | High-density insertion |

| 26 | Circuit board convey | Automatic, manual delivery |

| 12 | Machine size | 1992mm*1820mm*1593mm |

| 13 | Machine weight | 1200KG |

Compare the advantages and selling points of other standard equipment

1. Integrated design of the whole machine, smaller than the market machine, no need assembly, easy to place and install

2. The station integrated design is more conducive to daily operation and maintenance, smaller than the market machine, improves the continuity of feeding, avoids manual operation errors, and expands the scope of personnel operation (non professional personnel can also easily operate). Reduce accidents, reduce production costs.

3. The base adopts servo motor control and computer interface control operation, which improves the accuracy of product production. The operation difficulty of maintenance personnel is reduced and the noise pollution is reduced.