Product Category

Contact

sabrina.he@hjssmt.com

+86 15989403900

+86 15989403900

+86 15989403900

PCB Router Machine HJ-4500

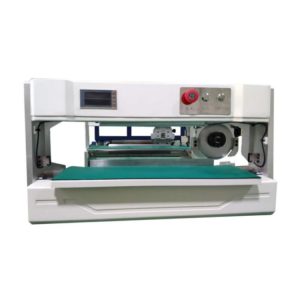

HJ-4500 automatic on-line PCB splitter is suitable for automatic production and automation equipment of unmanned chemical plant. Hn-4500 plate splitting machine is a plate splitting equipment with high performance, high precision, small land occupation and high efficiency.

HJ-4500 automatic on-line PCB splitter is suitable for automatic production and automation equipment of unmanned chemical plant. Hn-4500 plate splitting machine is a plate splitting equipment with high performance, high precision, small land occupation and high efficiency. It has the functions of automatic recognition of image mark point alignment, moving track position display and tracking, automatic milling cutter segmented cutting, output statistics and other parameters can be set. Negative pressure follow-up dust removal technology, secondary dust filtration dust collection device and electrostatic elimination device completely solve the problem of cutting dust. Automatic feeding and discharging can effectively improve production quality and save labor cost.

Product advantages: small space occupation, follow-up dust removal, high-precision visual edge finding cutting, DXF import function, automatic tool magazine, tool breaking and falling detection, bar code identification and MES connection. 12 inch industrial touch screen with mouse and keyboard, dual operation mode.

Milling Cutter:

Tool life display in production and automatic segmented cutting (three segments can be set) according to the distance set in the tool library to prolong the service life of the miller. According to the set cutting life of the tool, the function of automatic tool replacement is realized. Automatically identify whether the tool magazine has tools.

It adopts high pixel digital camera and large magnification lens, which can assist program teaching and editing simulation functions. Automatic mark positioning correction. The bar code reading function realizes the reading, saving or uploading of 1D / 2D bar codes, which is convenient for traceability and digital management.

Parameters:

| X/Y/Z Scope | 450*600*60mm |

| 620*700*60mm | |

| Applied Miller | Min:0.8mm |

| Max:3.0mm | |

| Cutting Speed | 0-100mm/s |

| Cutting Form | Straight line, circle, arc, U-shape, L-shape, etc |

| Idle Velocity | 60m/min |

| Electrostatic Elimination | SMC ion generator |

| Postion Accuracy | 0.01mm |

| Track Wideth Adjust | Automatic |

| PCB Direction | Left to right |

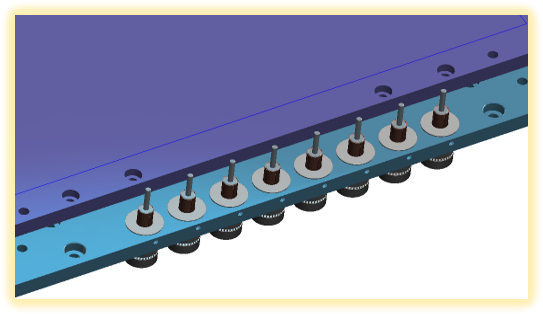

| PCB In/out Style | Vacumm Suction |

| Cutting Area | 330*330mm |

| 500*420mm | |

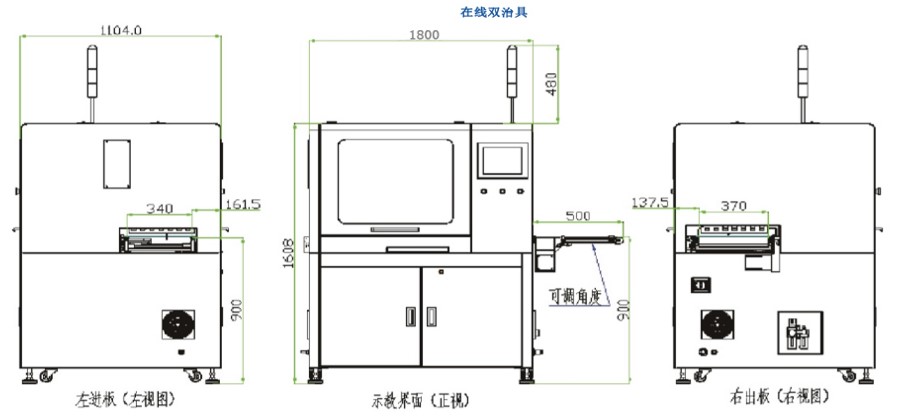

| Dimesion | 1800*1100*1600mm |

| 2032*1220*2088mm | |

| Weight | 900kg |

| Power Supply | AC220V/50HZ |

| Power Consumption | 1.5KW |

| Airl Consumption | 10N1/Min |

| Computer Software | Win7 |

| PCB Thickness | 0.6mm-5mm |

| HMI Screen | 12 inch industrial capacitor screen |

| Dust Collection | Lower type |

Size: