Product Category

Contact

sabrina.he@hjssmt.com

+86 15989403900

+86 15989403900

+86 15989403900

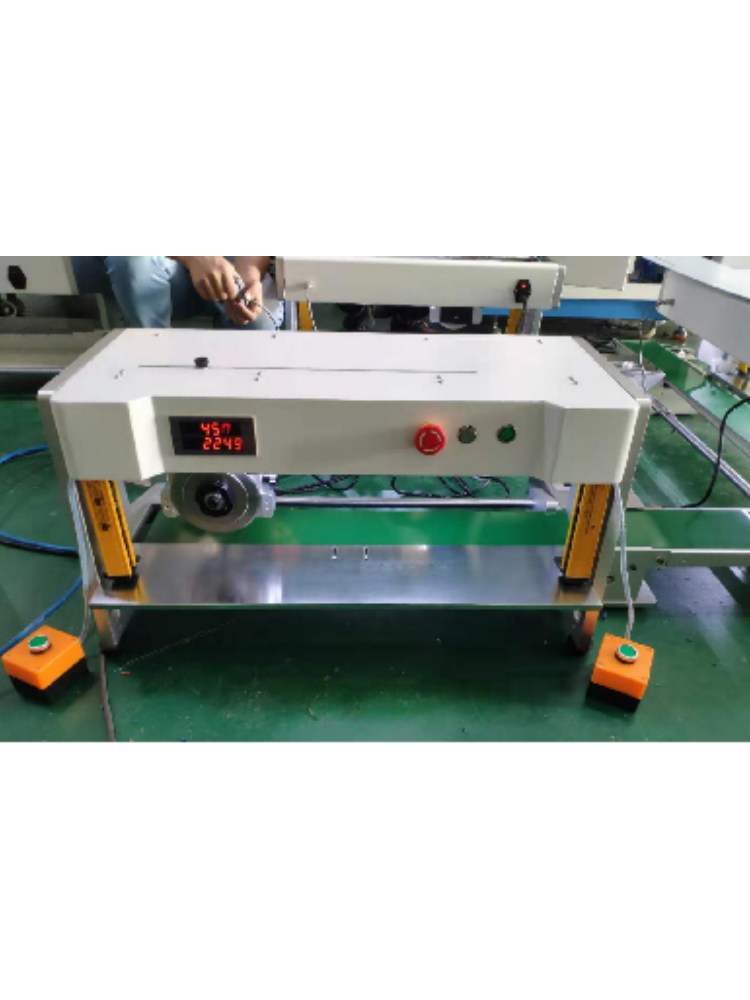

Blade Walking V-cutter with Conveyor HJ-300X

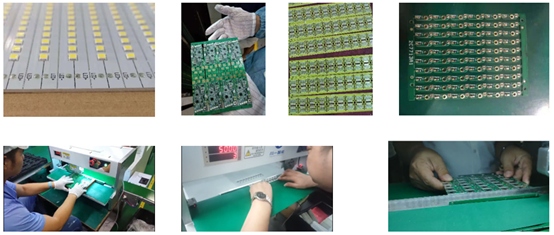

In the process of cutting traditional aluminum PCB, manual folding is used. Although the timeliness is fast, the electrical circuit, parts and tin track of aluminum substrate are often damaged due to the uneven force of manual folding and the difference in the angle position of the folding plate. In view of this, our company has developed V-CUT automatic cutting aluminum substrate machine to improve production quality and efficiency.

Blade Walking V-cutter with Conveyor HJ-300X

Specification parameters:

Power supply: 220V, 50 / 60Hz, 250W

Weight: net weight 50kg

Plate feeding speed: 300 ~ 500mm (with conveyor belt)

Larger length: more than 400mm; plate thickness: 0.2 ~ 3.2mm

Working temperature: 10 ~ 35 ℃

Storage temperature: - 20 ~ 50 ℃

Overall dimension: 670mm (L) * 530mm (W) * 440mm (H)

Features:

1. The aluminum substrate of the special V-CUT is used for plate splitting to stabilize the operating mechanism and prevent the circuit board tin track surface, electronic parts solder joints, and other electrical circuits from being damaged due to improper external forces.

2. The special round knife material design ensures the smoothness of the split surface of the aluminum substrate.

3. Fine adjustment of cutter wheel: 0-2mm, adjustable lower plate cutter: 0-50mm

4. The cutting stroke distance can be adjusted in five sections, 0 / 100 / 200, 300 / 400, to quickly switch different circuit board sizes.

5. The height of the upper knife can be adjusted according to the plate and plate thickness to better cut accurately. The cutting thickness is 0.6-3.0mm, and the remaining thickness of the standard V-groove is 1 / 3

6. High frequency eye protection lighting device improves the operation quality of operators.

7. A conveyor belt can be added, and the aluminum substrate can be automatically sent out of the cutter position

8. Safety light curtain device can be installed to avoid human negligence.

Operation:

1. It is divided by walking knife, which can completely reduce the stress and prevent the cracking of welding spots and parts.

2. The upper round knife and the lower flat knife are used. The aluminum substrate is placed on the lower flat knife. Once the switch is pressed, the upper round knife moves linearly and horizontally to the set point, that is, the aluminum substrate is cut and divided, and the cut is flat without wire falling off.

3. The cutting speed can be set to high and low.

Technical parameters:

A: Cutting thickness of aluminum substrate (mm): 0.6 ~ 3.2

B: Minimum dimension of V-groove (mm): 0.25

C: V-groove cutting thickness of aluminum substrate (mm): 0.3 ~ 0.8

D: Minimum distance between element and plate groove (mm): 1.00mm

E: Larger height of aluminum substrate components (mm): 35

F: Adjustable lower plate (mm): 0-50mm.

Scope of use:

SMT pcb. Circuit board, aluminum substrate and glass fiber board with V-CUT can be selected.