Product Category

Contact

sabrina.he@hjssmt.com

+86 15989403900

+86 15989403900

+86 15989403900

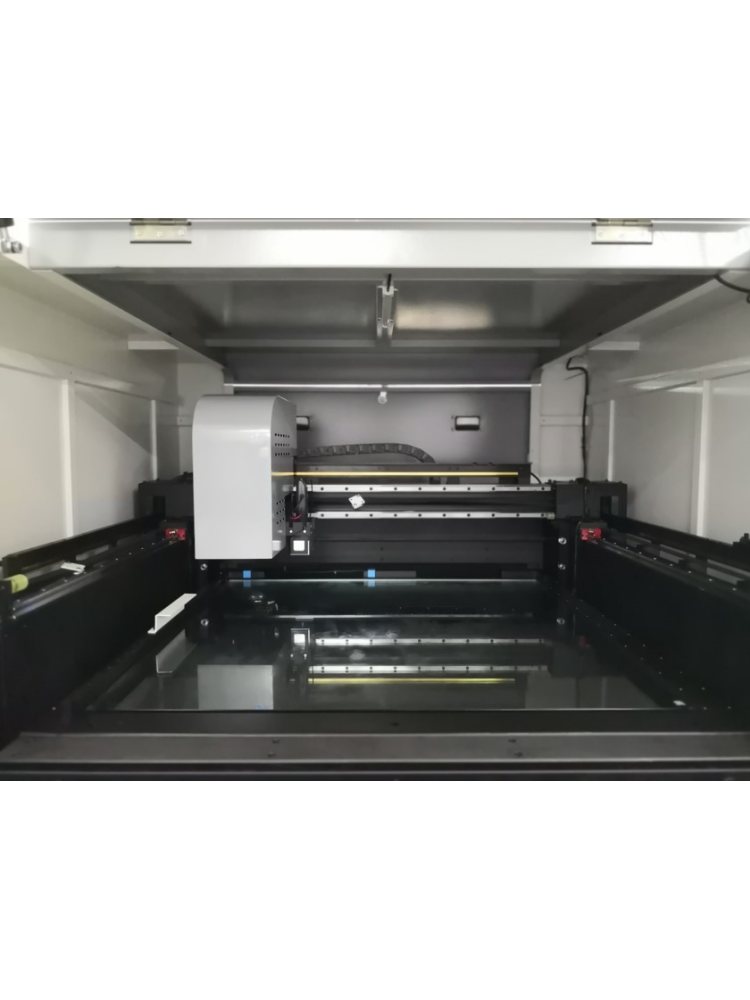

Automatic Stencil Inspection Machine HJS-2800

Measurement principle:

• Using the automatic image measurement technology, through the measurement of the parameters such as the opening size and position of the stencil, set the error range and compare it with the reference value to judge whether it is qualified or not.

• The operation is simple and the measurement process is completed automatically, which not only greatly improves the detection accuracy and speed, but also avoids human judgment factors, and provides direct quantitative data for judging the quality of steel mesh.

• Function:

Comparative measurement of stencil opening to Gerber document.

Comparative measurement of new and old stencil.

Comparative measurement of stencil opening on PCB pad

Features:

Minimum inspection size: 30x30 μ m. Applicable to: quality inspection of semiconductor and SMT steel mesh

Programming through Gerber file can be completed in 3 ~ 5 minutes

Steel mesh opening inspection requires full coverage

Microscopic visual observation of steel mesh wall

Visual measurement of stepped steel mesh thickness

High precision tension measurement scheme

Inspection for poor opening of the whole plate

high precision:

Concept design of high precision measuring equipment

Class 00 marble platform to ensure the accuracy and stability of the equipment platform. The natural floating assembly method is adopted to keep it natural and free from external forces; The fully cast gantry structure is processed by natural aging, stress release process and finishing to ensure the stability and high precision of the moving mechanism

High precision and high-speed non-contact grating ruler (Renishaw brand in the UK), combined with software and machinery, carries out closed-loop control of motion positioning accuracy to ensure mechanical positioning accuracy

The whole board is photographed and scanned in flight, and the whole board detection is completed in 3 minutes

6.9um resolution German IDS high-end industrial camera

The top ring LED light source, combined with the follow-up high-performance coaxial led bottom light source, has strong penetration, reduces the halo phenomenon and ensures the clear imaging of the opening edge

The z-axis height movement system can cope with various specifications of steel mesh and meet the requirements of automatic tension test

Process Research window:

Virtual printing function

1. Comparison and analysis of stencil Gerber

• 2. Comparative analysis of PCB Gerber

3. PCB physical scanning and comparison

4. Physical scanning, detection and comparison of stencil

The above four points are fully combined with the function of comparative analysis to check the differences in the opening process of stencil

Simulate the amount of tin under the steel mesh in advance to provide objective data required for process analysis.

grouping and grading method:

For openings of different sizes, component types and levels, use different levels of detection parameters to better ensure the accuracy of high-precision components

Exclusive 3D steel mesh thickness measurement technology:

Based on the principle of triangulation, the thickness of steel plate and the smoothness of hole wall are measured with a special 3D thickness measurement camera corresponding to the 45 degree angle of hole wall. t=h*sina; Through the 3D angle camera, the thickness of the opening is observed and calculated in real time. Measurement resolution: 0.12um, measurement accuracy: 1.2um

Nano coating: screen thickness measurement and hole wall quality observation